Overview

A leading Turkish dairy company was eager to ensure that the water facilities serving more than 20,000 heads of cattle (mainly cows), were safe and free of bacteria and other harmful microbes. The disinfection process that was being used was not meeting the requirements and was directly affecting the cattle health, fatality rate and milk productivity, and in turn disrupting the overall productivity of the production facilities.

To secure a sustainable solution for this requirement, the firm reached out to Info Group, a Metito Company, to consult on this matter.

Info Group conducted a thorough review of the water treatment process at one of the facilities that uses 4000 m3 per day from various nearby wells, from an intensively agricultural region. Expectedly, fertilizer contaminants were present in the water, which deteriorates the quality of the sourced water, and there was also present biological contamination.

Info Group and the client agreed that the best way forward was to develop a sustainable solution to eliminate the presence of pathogens from the water and to assure a consistent supply quality water – up to standards – across the facility.

Solution

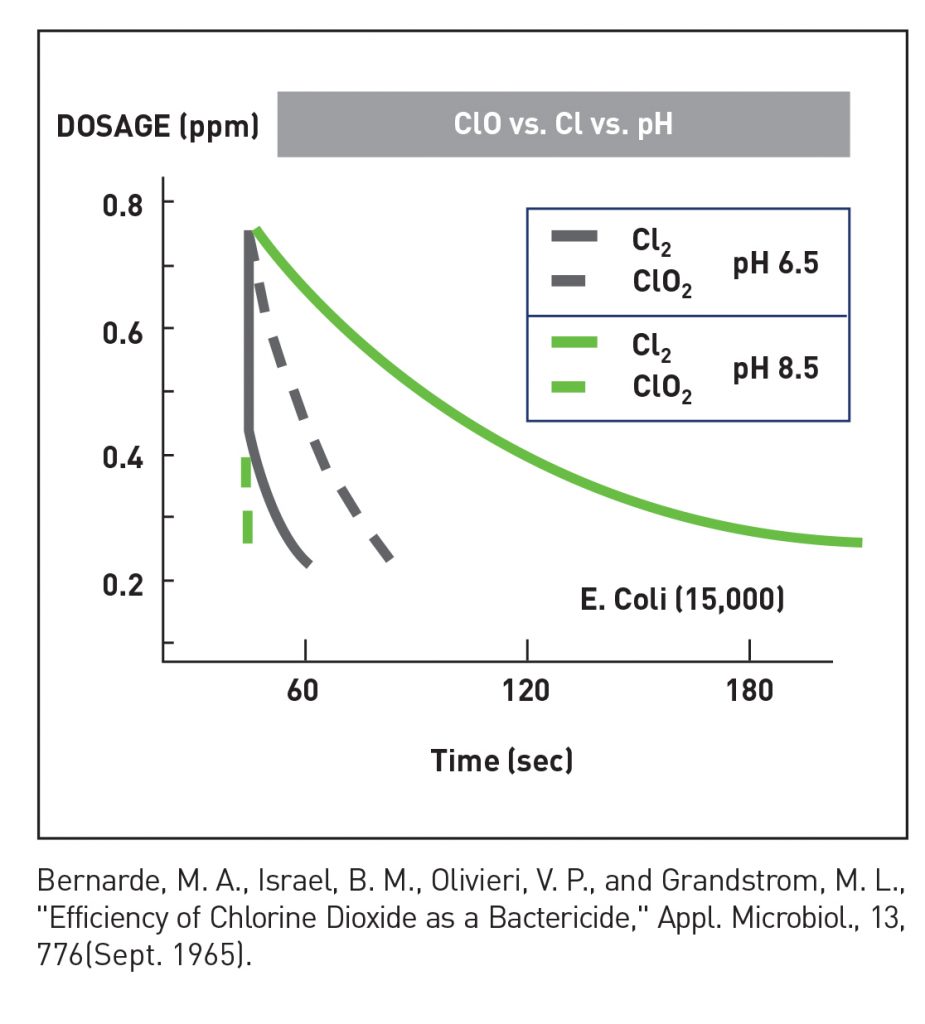

Info Group conducted a root cause analysis and examined the surrounding environment, the groundwater quality and current treatment process. The findings indicated a surge in metal ions (Fe and Mn) levels and an increase in bio-activity (E.Coli increased from nil to 103 CFU and fecal coliform was tested positive). Moreover, the water pH was fluctuating between 7.2 and 8.3, hindering the disinfection by the current program.

Based on the study, it was decided to implement a new approach to overcome the challenges at the source and at the facility where water is used in order to restore the water quality, cattle health, optimize operations and maximize productivity.

Info Group new approach was based on Metito’s Chlorine Dioxide on-site generation technology using CCDS-100 model, to secure the best in class – the most reliable- disinfection water treatment. The team also developed a customized disinfection program for locations which had higher risk of bacteria growth and pathogens.

The selection of Chlorine dioxide was based on its unique disinfection capability over a wide pH range, fast reactivity with the bacteria due to higher oxidation potential, and stable disinfection power. This was confirmed by the results obtained from all facilities upon implementation. With such a solution we ensured a stable treatment and a sustainable supply of clean and safe water which exceeds the requirements of the production facilities and the cattle farm.

| Microorganisms | ppm ClO2 | Contact Time | Disinfection Rate (%) |

|---|---|---|---|

| Staphylococ. | 1,00 | 60 sec. | >99,9 |

| Escherichia | 0,15 | 5 min. | |

| Escherichia coli | 0,2 | 60 sec. | |

| Streptococcus Faecali | 1,0 | 15 sec. | |

| Lactobacillus | 0,15 | 5 min. | |

| Lactobacillus | 1 | 5 min. | |

| Pseudomonas | 1 | 60 sec. |

Financial and Operational Benefits

- 95% reduction in cattle fatality

- Healthier cattle condition (lower illness rate)

- Increase in the rate of milk production

- Recovery in dairy facility productivity

- Improved water resource management in accordance to the highest standards

Result

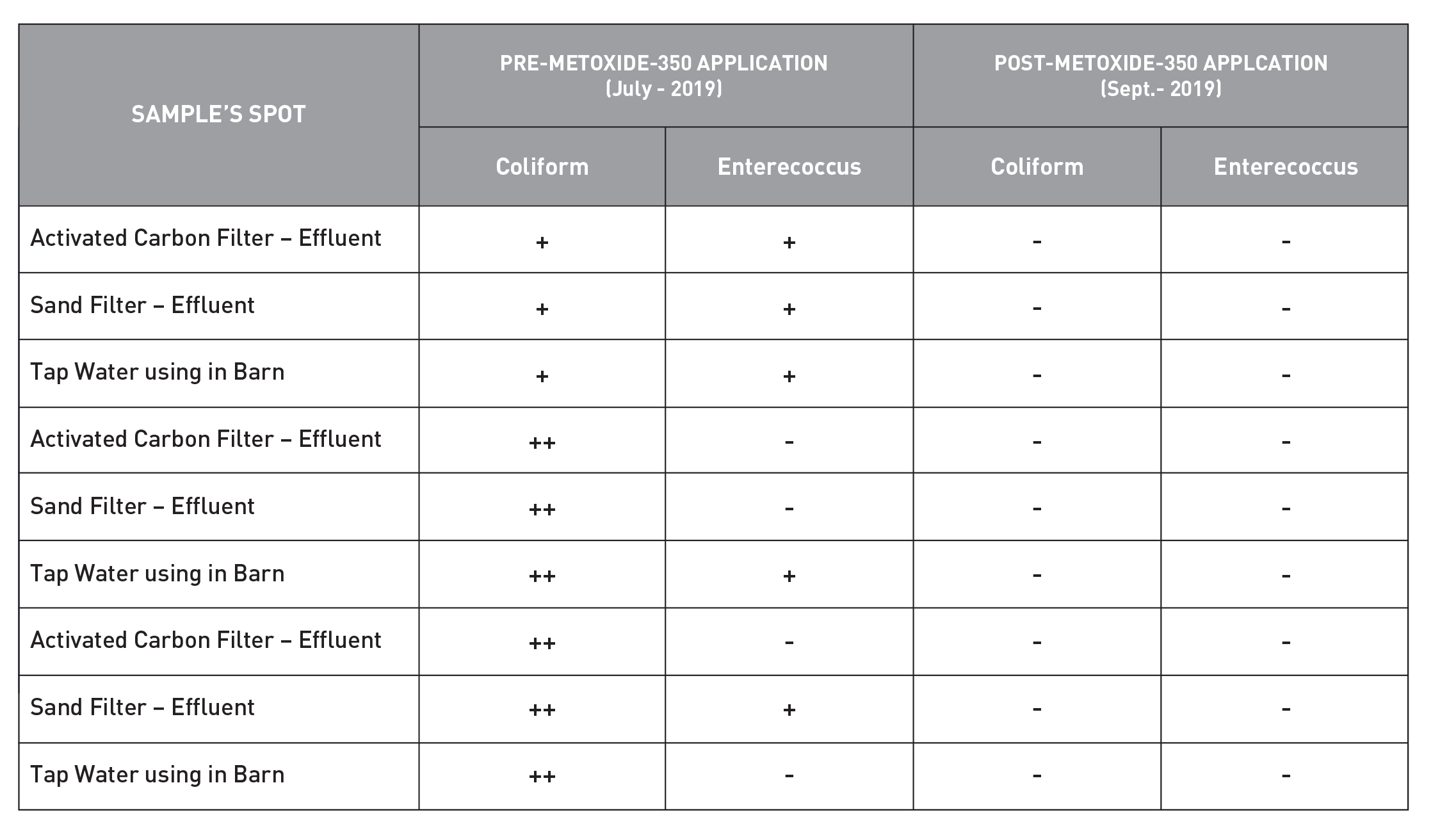

Post application analysis showed improvement in disinfection efficiency and microbiological control.

- Prevention of coliform bacteria growth, thus eradication main reason of water related fatality

- Increase in operational efficiency

- Optimization of lost time by detecting and notifying failures

- Control of main water tanks contamination

- Shorter CIP time / increase in production rate

- Reliable supply of quality water with tailored automation